Hydro-X’s new range of PTSA Inhibitors:

- Now standard as part of our liquid range of cooling system inhibitors

- Integrated into our new range of solid Hydro-Solv chemicals

Field Example:

Quite often when new cooling systems are brought on live there is a disconnect between original procurement, handover/practical completion and ongoing maintenance in line with manufacturers warranties.

A key client engaged with Hydro-X early in the process which resulted in shorter, and longer, term benefits. These included:

- Review of original manufacturer specification (based on non-UK with little to no knowledge of HSG274 legislation)

- Challenge of water specification (this was a copy of a previous project which was not fit for local water chemistry)

- Based on a ‘one-time’ throughput, so high water usage in an area where water is becoming a more expensive commodity

- No longer term maintenance programme in place to protect the systems/be at its most efficient for day one.

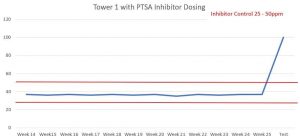

Hydro-X undertook a detailed cost benefit analysis which determined the need to specify fit for purpose pre-treatment and dosing equipment at build stage. This would allow visibility of key performance indicators which included corrosion, deposition and bacteria monitoring from the very start of the project. Using the ‘Hydro-Solv’ synergic blend of corrosion and scale inhibitors with PTSA technology, the customer was able to have confidence that the right product was being dosed at the right levels, all of the time.

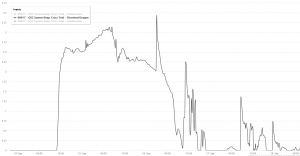

Coupled with Hydro-X’s online dashboard, ‘Hydro-Net’, both parties were able to have the confidence to move quickly through PC. From early in the maintenance contract there was commitment to drive for higher cycles of concentration: a calculated risk that brought highly tangible early reward. This included optimised water and salt usage that made best use of available space with highly predictable water consumption to fix budgets and minimise unplanned spend.

Although Hydro-X manufactures its own products in the UK, the reduction in carbon footprint via less transportation vehicles travelling to site was still not insignificant. In addition, it has all but eliminated manual handling and disposal of empty containers.

Hydro-X has over 2500 days of continued operation without a RIIDOR. Safe, compliant working is an integral part of Hydro-X’s business culture. This case study is a key part of the customer sustainability targets both on site and globally within their organisation.

At a recent client legionella audit, the ‘Hydro-Net’ system was utilised to show trending and reporting that enabled the auditor to have all the answers they needed around legionella risk management.