Fire Stopping

Ensure your Fire Dampers are Compliant

What is fire stopping?

Fire stopping is commonly used to seal the fire compartment where services penetrate through the walls, floors, and ceilings. The voids created to allow the passage of services through a structure are not made to fit the services passing through them, and sometimes the services are re-routed entirely, and thus the gaps need to be filled using an appropriate fire-retardant material and seal.

Why do fire barriers need to be inspected?

Regular inspection of the fire compartments located throughout the building are required to verify:

The fire compartment is completely sealed

The fire compartment needs to be completely sealed to be able to contain the fire and the smoke it produces. Any penetrations through the fire barrier will allow fire and smoke to spread, reducing the effectiveness of the fire barrier or rendering it completely ineffective.

Ensure effectiveness of the individual components of the fire compartment

If any component of the fire barrier (Fire damper, Intumescent Pipe Collar, Fire Batt., etc.) is installed incorrectly installed, or not completely sealed into the fire barrier, this will allow the fire to penetrate around the component. This encircling of the component will reduce its effectiveness and greatly diminish the fire-retardant properties of it.

Regulations ASFP Red Book, RRO 2005

Request a callback

Why do fire barriers need to be sealed across the fire compartment?

It is imperative that all components that make up the fire compartment are correctly installed a sealed. Any part that is not correctly sealed will offer an escape route for fire and smoke and will greatly diminish the effectiveness of the compartment as a whole.

The best way to ensure that there is an adequate seal it to make sure that a competent qualified and regulated installer carries out the works and that the firestopping components used are from the same manufacturer and system. (Please refer to ASFP Advisory note 6)

The BESA – Fire Stopping of Service Penetrations – Best Practice in Design and Installation

Approved Document B (England clause 10.2) and Wales (clause 11.2) states:

“If a fire separating element is to be effective, then every joint, or imperfection of fit, or opening to allow services to pass through the element, should be adequately protected by sealing or fire-stopping so that the fire resistance of the element is not impaired”

What are the responsibilities regarding fire stopping?

As the building owner / responsible person on-site you need to ensure that all fire and smoke dampers within your building(s) are located, serviced, and tested (whether that be a drop test or otherwise). Hydro-X Fire can help to ensure you meet the regulatory requirements and support you in compiling an asset list and schedule to ensure regular checks are carried out and any defects are remedied for continued safe operation.

According to the Regulatory Reform (Fire Safety) Order 2005, it is the employer’s responsibility to maintain their fire safety systems.

- As the buildings responsible person if you are made aware of faults to any fire safety equipment and do not act on them, you could be held responsible for any implications and be prosecuted in a court of law.

- If you run a business or own a building it is your responsibility to book regular fire damper tests and ensures that a proper maintenance plan is followed.

With the enactment of the Regulatory Reform (Fire Safety) Order 2005, it is now the employer’s responsibility to maintain their fire safety systems.

BS 9999 Annex W.1 Inspection and Maintenance states that:

Arrangements should be made for all fire dampers to be tested by a competent person on completion of the installation and at least annually, and to be repaired or replaced immediately if found to be faulty. Spring-operated fire dampers should be tested annually, and fire dampers situated in dust-laden and similar atmospheres should be tested much more frequently, at periods suited to the degree of pollution.

BS 9999 Annex W.1 Inspection and Maintenance (Note 1) states that:

NOTE 1 Maintenance of air conditioning and ventilating equipment, including air filters, motors, fire dampers and their controls, smoke detectors and alarms, is of paramount importance both in preventing fire and in ensuring that measures taken to mitigate its consequences are effective when needed.These publications are supported by the existing BESA publications with DW145 – Installation and Maintenance of Fire and Smoke Dampers currently under review.

At Hydro-X Fire, not only can we complete the fire damper installation and replacement, but we can also assist with the following fire damper services:

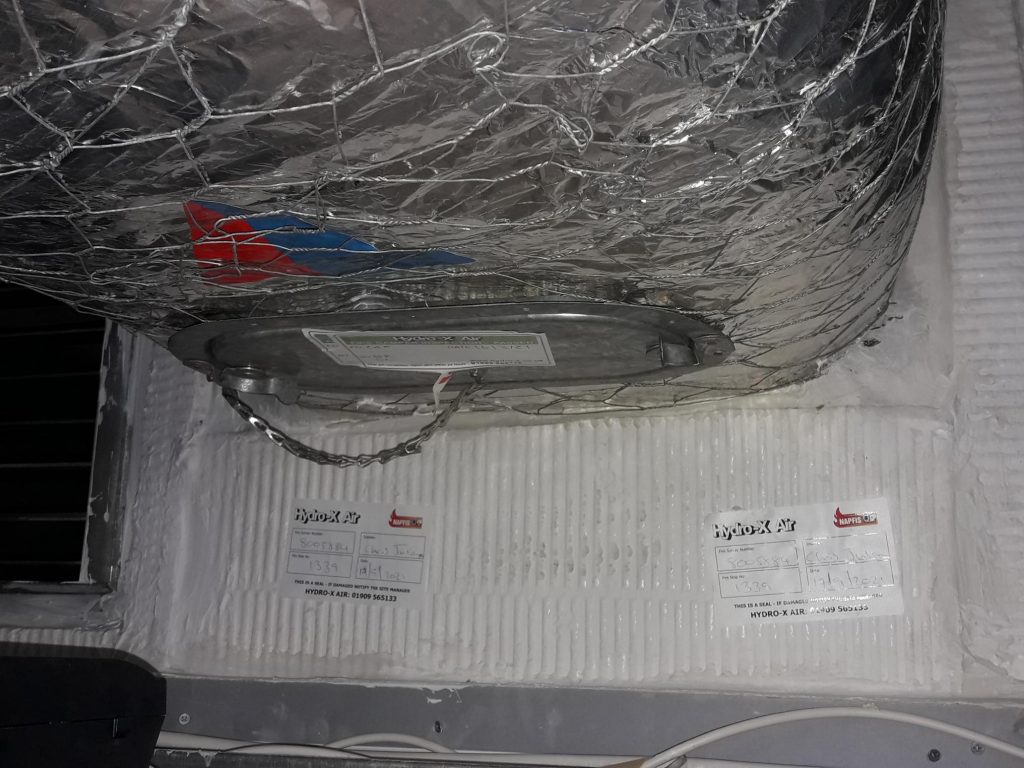

Fire damper installation & replacement

These come in many forms from small perforation to fire damper units located completely outside of the fire break.

This should be carried out by law at least on a 12-monthly basis.

Fusible Link Sourcing & Replacement:

These com in many forms and sizes and are a vital piece in the functionality of the fire damper and efficiency of the HVAC system

BS 9999 Annex W.1 Inspection and Maintenance (Note 2) states that: “The provision of access panels facilitates such cleansing, other maintenance, and also fire-fighting.”

DW145– Installation and Maintenance of Fire and Smoke Dampers states that the installation of a DW144 access door is a requirement for testing purposes.

TR19 – Internal Cleanliness of Ventilation Systems states that a DW144 access door is required either side of the fire damper unit for cleaning purposes.

Hydro-X Fire will analyse the above fire damper defects and suggest the most efficient solution possible. For further fire damper remedial information or to get a quote please use the contact sheet below.

> Enquire about our Fire Damper Remedial work services

> View our other Fire services