Fusible Links

Ensure your Fire Dampers are Compliant

What is a fusible link?

Thermal fusible links come in many different shapes, sizes, and temperature ratings. Usually rated to trigger at a temperature of 72˚C in fire dampers the maintenance and replacement of these is a vital part in the functionality of a buildings passive fire protection.

They are used to maintain a fire dampers blades in the open position. Once they reach the rated temperature, they will trigger releasing the fire damper blades and allowing it to shut and seal the firewall at the point where the ductwork penetrates through, thus preventing the spread of fire (And smoke in the case of Fire & Smoke dampers) through the ductwork.

How do I maintain and check fusible links for faults?

The maintenance and replacement of faulty fusible links is part of the buildings fire damper drop testing (To be performed by law at least every 12 months).

For more information on fire damper drop testing please refer to our Fire Damper Drop Testing service page

Request a callback

Why do fusible links need to be maintained and replaced when faulty?

As these are an important part in the functionality of the fire damper, their maintenance is equally important so that in the case of a fire the fire damper will function correctly.

Lack of maintenance can lead to multiple issues such as:

Dirt build-up on the fusible link causing reduced performance, premature wear and in extreme cases can act as an insulation increasing the temperature rating and increasing the risk of fire propagation outside of the fire compartment

Broken fusible link allowing the fire damper to close and obstruct overall air circulation through the HVAC system

Damaged fusible link caused by general wear over time, excessive vibration in the ductwork or using the wrong grade of fusible link for the type of fire damper installed. This can cause the fire damper to trigger prematurely or interfere with the functionality of the fire damper

Seized link impeding the drop testing of the fire damper and in some cases can prevent the fire damper from triggering entirely if the link does not release when triggered

What are the responsibilities regarding testing & maintenance?

As the building owner / responsible person on-site you need to ensure that all fire and smoke dampers within your building(s) are located, serviced, and tested (whether that be a drop test or otherwise). Hydro-X Fire can help to ensure you meet the regulatory requirements and support you in compiling an asset list and schedule to ensure regular checks are carried out and any defects are remedied for continued safe operation.

According to the Regulatory Reform (Fire Safety) Order 2005, it is the employer’s responsibility to maintain their fire safety systems.

- As the buildings responsible person if you are made aware of faults to any fire safety equipment and do not act on them, you could be held responsible for any implications and be prosecuted in a court of law.

- If you run a business or own a building it is your responsibility to book regular fire damper tests and ensures that a proper maintenance plan is followed.

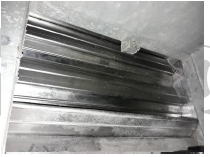

Seized Fusible Link

Damaged Fusible Link

With the enactment of the Regulatory Reform (Fire Safety) Order 2005, it is now the employer’s responsibility to maintain their fire safety systems.

BS 9999 Annex W.1 Inspection and Maintenance states that:

Arrangements should be made for all fire dampers to be tested by a competent person on completion of the installation and at least annually, and to be repaired or replaced immediately if found to be faulty. Spring-operated fire dampers should be tested annually, and fire dampers situated in dust-laden and similar atmospheres should be tested much more frequently, at periods suited to the degree of pollution.

BS 9999 Annex W.1 Inspection and Maintenance (Note 1) states that:

NOTE 1 Maintenance of air conditioning and ventilating equipment, including air filters, motors, fire dampers and their controls, smoke detectors and alarms, is of paramount importance both in preventing fire and in ensuring that measures taken to mitigate its consequences are effective when needed.

These publications are supported by the existing BESA publications with DW145 – Installation and Maintenance of Fire and Smoke Dampers currently under review.

At Hydro-X Fire, not only can we complete the fire damper installation and replacement, but we can also assist with the following fire damper services:

Fire damper installation & replacement

These come in many forms from small perforation to fire damper units located completely outside of the fire break.

This should be carried out by law at least on a 12-monthly basis.

Fire Compartmentalisation Failure:

These come in many forms from small perforation to fire damper units located completely outside of the fire break.

DW144 Access Panel Installation:

BS 9999 Annex W.1 Inspection and Maintenance (Note 2) states that: “The provision of access panels facilitates such cleansing, other maintenance, and also fire-fighting.”

Hydro-X Fire will analyse the above fire damper defects and suggest the most efficient solution possible. For further fire damper remedial information or to get a quote please use the contact sheet below.

> Enquire about our Fire Damper Remedial work services

> View our other Fire services