Hydro- X Water introduces its Innovative

HydroSafe Chlorine Dioxide System

Chlorine Dioxide has been around for many years and is recognised as a powerful oxidizing biocide. Studies over the years confirm its efficacy in controlling microbial activity, including Legionella and Biofouling in Domestic hot and cold-water systems, process systems, boreholes, and cooling systems.

Over the years, various methods of generating Chlorine Dioxide have been adopted, with various levels of success and conversion reaction efficiencies.

Going back as far as the HSE HSG70, the research carried out by BSIRA and association of Biofilm as a contributing factor for colonisation of Legionella. MISC 150 was issued as a supplement to the HSE HSG70 in recognition that supplementary treatments other than Temperature to control Legionella should be considered as a review of a compromised control scheme. Most recently we have the HSE’s HSG274 and the AcoP L8, which still talks about the benefits of supplementary treatment or primary method of control over temperature. As such, we have seen over the years various manufacturers producing Chlorine Dioxide systems. The challenge has always been the ability to convert the reaction conversion efficiency of the potential yield. Do this safely and without risk.

The challenge has always been when treating a Domestic Drink Water System, to coincide with the required of the Drinking Water Inspectorate. The total oxidants should be no greater than 0.5ppm, including Chlorite, Chlorate and Chlorine Dioxide. BSRIA research concluded that to rid and prevent Biofouling, a minimum of 0.4ppm of Chlorine Dioxide would be required.

This is where the challenge lays – Many Chlorine Dioxide generators do not have the capacity to produce a reaction conversion efficiency to allow this. Most 2 pack Chlorine Dioxide generators produce a conversion reaction efficiency of circa 45 – 70%. This means there is a high percentage of unreacted Chlorite associated with the product steam and as such adding to the total oxidants of the water distribution. This means that it is impossible to achieve the 0.4ppm to rid and prevent Biofouling without exceeding the DWI total oxidant levels. Why is this important? Whilst lower levels of Chlorine Dioxide reserves can indeed kill off planktonic Legionella (free floating) and there may be some ability to penetrate and remove/kill some biofouling, this can be detriment to the overall treatment efficacy. By partially cleaning a system, this can often lead to spikes in Legionella being isolated as organic loading and oxidative demands change within the system, reseeding due to Chlorine Dioxide levels fluctuation as a result of this.

It is therefore vitally important when choosing a Chlorine Dioxide system this is taken into consideration. To enable the 0.4ppm of Chlorine Dioxide without exceeding the DWIs total oxidant limit of no greater than 0.5ppm, the conversion reaction efficiency should be >80%. HTM04 recognises this and it actually stipulates that in healthcare facilities, a Chlorine Dioxide generator should provide a conversion reaction efficiency of >90%.

In addition to this, it is vitally important to ensure that the production on Chlorine Dioxide is such that it doesn’t compromise health and safety. Many Chlorine Dioxide generators, generate Chlorine Dioxide in pressure reaction vessels of up to 65000ppm, which is indeed very gaseous. Should this reaction chamber fail, Chlorine Dioxide gas would be released, and health and safety would be compromised. Also, many manufacturers have tried to get around this process of reaction by means of dosing Acid and Chlorite into a reaction block straight into the water distribution system, this resulting in lots of unreacted Chlorite as a result of poor reaction holding index time to throw the fully possible conversion. There are some systems that just dose Acid and Chlorite straight into the water distribution with no mixing. So, there is lots to consider.

Hydro-X recognise the huge benefits in using Chlorine Dioxide as a primary or secondary method of control and the challenges in producing it, safely, efficiency and effectively without compromising health and safety.

Considering these challenges, Hydro-X have invested time and capital into the development of its “HydroSafe” Chlorine Dioxide Generator. “A Chlorine Dioxide Generator of the future being delivered today”

They HydroSafe Chlorine Dioxide generator produces Chlorine Dioxide to (BSEN12671) using 9% Hydrochloric Acid and 7.5% Sodium Chlorite. The reaction is held for a set period of time to allow the full conversion to take place, (Conversion reaction efficiency of >98% of the yield) before instantaneously diluting the reaction to a specific PPM level where stabilisation takes place. This unique feature allows stabilisation for up to 12 weeks, this ensuring that there is no degradation in its production of Chlorine Dioxide ensuring that all of the Chlorine Dioxide is available to dose to the water system without the build-up of Chlorite – thereby not compromising the requirements as set out by the DWI of a maximum total oxidant level of 0.5ppm. This ensuring that we can achieve the 0.4ppm of Chlorine Dioxide to rid and prevent Biofouling.

Once the Chlorine Dioxide has been produced, the Chlorine Dioxide is introduced to the water system by its intelligent stepper motor dosing pump, receiving micro pulses from the intelligent water metering system to allow a precise prescribed amount of Chlorine Dioxide to be dosed in conjunction with the flow rate and water usage. This provides straight line control of Chlorine Dioxide rather than peaks and troughs.

The additional Features of this system are:

- Gas detection and failsafe shut down

- Intelligent metering and chemical usage to cross ref reaction efficiency

- Ion Specific Probes, Chlorine Dioxide and Sodium Chlorite

- Audible Alarm

- Integrated recirculation assembly with integral jockey pump

- Static mixing manifold

- Colour coding dosing lines, dosing pumps and tanks and bunds

- Pass protected PLC and Control

- Full remote telemetry as standard with customer portal for view integration with hierarchy accessibility.

- Data recording and data-based records with historic evidence

- Simple plug and play installation

Hydro-X Group is extremely pleased to announce the launch of its next generation Chlorine Dioxide Generator – HydroSafe.

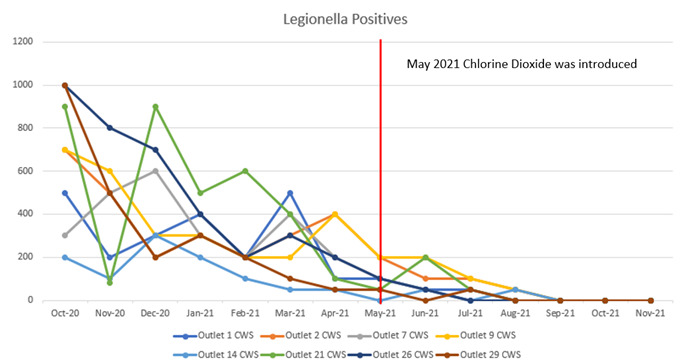

We recognise the importance of managing a water system is key to the prevention of Legionella and over the last couple of years, many water systems where buildings have been left unoccupied or with reduced capacity, controlling legionella has become even more of a challenge. We have had many new customers come to us for support in helping them to maintain their water systems. An example below shows an office block where there was a significant reduction in staff and the water system had quickly become colonised with Legionella. Various disinfections/ flushing regimes were carried out as part of the overall remediation program. Levels of Legionella throughout the remediation albeit reduced somewhat, but full eradication was proving very difficult until the client agreed to install based on our recommendation, our HydroSafe Chlorine Dioxide generator.

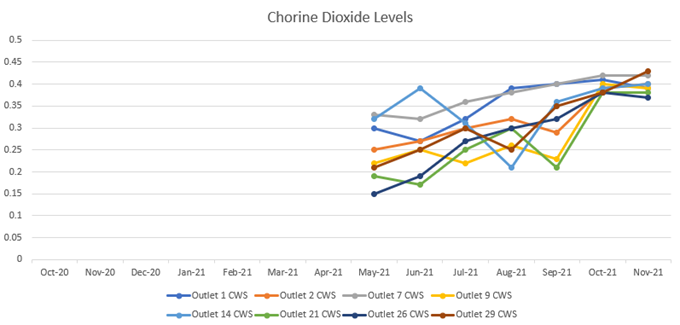

As you can see by the graphs, levels fluctuated as a result of remediation, but we never did see the full eradication. You will notice that the Chlorine Dioxide levels fluctuated initially until the cleaning of the system had been achieved and the obvious biofouling being removed. Dosing levels set at 0.5ppm see recorded levels of between 0.2 and 0.3 indicating the oxidative and organic loading these levels steadily increased over the months to 0.39 – 0.42ppm and the last few months eradicating Legionella totally. This all being monitored remotely, and data collection being held on the client portal.

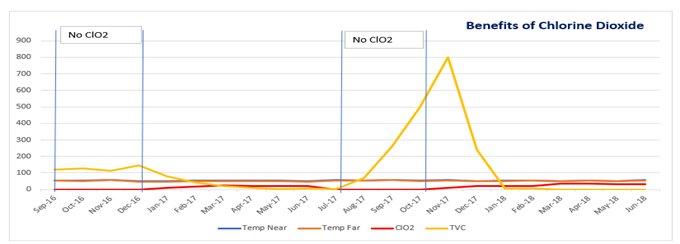

As you can see from figure 3.0, the yellow line indicates levels of microbial activity during September and December 2016. In January 2017, Chlorine Dioxide was dosed to the water system and the levels of Microbial activity declined trough January to July 2017. The client considered this as now being under control and asked that the Chlorine Dioxide unit be switch off. As you can clearly see the levels of Microbial activity soon elevated through August, peaking in November 2017. Note: The Chlorine Dioxide system was switched back on the end of October 2017. It then took 4 further months to bring the system back in control due to the colonisation and probable Biofilm build up whilst the system wasn’t being treated with Chlorine Dioxide. This is as a result of a clean system being quickly colonised after a clean up and microbes laying down the likes of biofouling due to an abundance of nutrients coming in with the water and/or bad system design and no system protection. This shows the importance of continuing to treat a problematic system all of the time.

If you want more information or are interested in a free survey, please contact adam.griffith@hydro-x.co.uk