Steam Raising Plant – How to Reduce Fuel Costs

Most businesses with a Steam Boiler recognise the importance of making sure that it is well maintained to ensure that there is no down time as a result of failure resulting is loss of production.

Most Steam raising plants are the beating heart of the overall process and poor water treatment is often blamed for plant failure.

Hydro-X recognises the importance of ensuring that their Water Treatment packages are tailored to ensure optimum performance of the overall treatment program and critical water treatment plant that provide water make up.

With ever increasing fuel costs, it is even more important to ensure that optimisation is maintained all of the time, but we often find that when surveying potential customer sites, this isn’t the case. Often finding poor water treatment chemistry, low cycles of concentration and low TDS as a result of the poor Water Treatment control – this also results in increased water and energy usage.

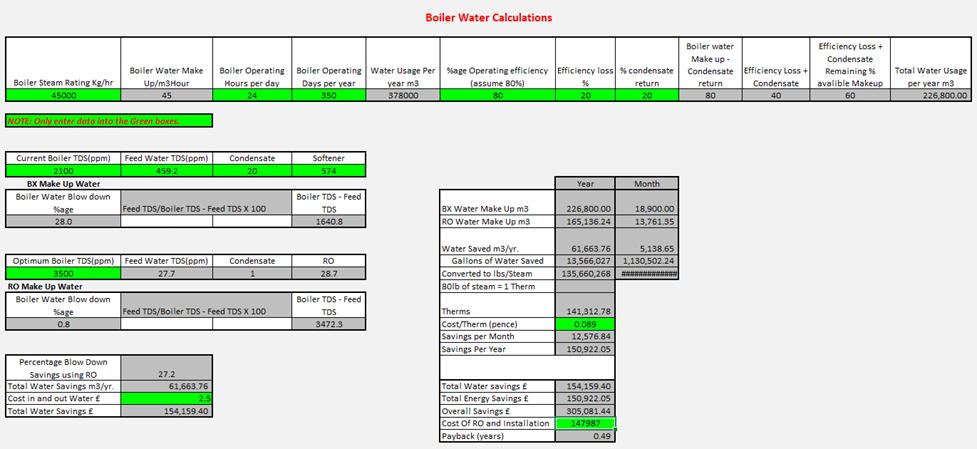

An example below demonstrates some of the findings and how we have looked at the overall treatment program and with investment saving some of our prospective/new customer circa 2 – 5% in energy which is substantial.

Case Study – Food manufacturer in East Anglia

Steam Raised 45000kg/hr

Make up water BX Soft Water TDS 574ppm

Boiler water TDS 2100ppm average control

Condensate Return 20%

By installing a RO (Reverse Osmosis) reducing the water up water TDS and Increasing the Boiler TDS saves circa 27.2% in blowdown and wasted energy to reheat the make-up water that is required to top up as a result of Blowdowns. Saving Circa of 61700m3 of water from been blow down the drain. And chemical which ends up at the effluent plant to be treated.

Total water savings £154,159

Total energy savings £150,922

Combined savings £305,081

Capital investment for a RO Plant £147,987

Return on investment 0.49 months.

This calculator demonstrates how we can help you

To find out more about how Hydro-X can help you save money on both energy and water whilst maintaining your steam raising plant at it’s optimum performance, please contact info@hydro-x.com