Fire Damper Testing and Maintenance

Ensure your Fire Dampers are Compliant

What is a Fire Damper?

Fire and smoke dampers are fitted in ductwork to prevent the spread of fire, they are usually used whenever there is a fire resistance wall (which is why fire damper testing is so necessary). Fire dampers are responsible for slowing or stopping a fire inside of a Heating, Ventilation and Air Conditioning (HVAC) system, helping to minimise any damage to the structure itself and most importantly to protect the people within the building.

Why do Fire and Smoke Dampers fail?

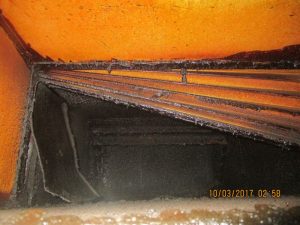

Foreign materials and particulates such as dirt, combustible dust, and debris can accumulate within the ductwork. These foreign materials can impair the proper functioning of the fire dampers, leaving the building occupants at risk in the event of a fire. Typical issues also include obstructions to access the fire damper, poor installation hinges damage to parts , misalignment, bent tracks, damper coil spring twist, corrosion, heavy contamination, transit stap in situ rust, or damaged frames or blades.

It might take only one faulty damper to allow the spread of a fire, therefore it is imperative annual fire damper testing (i.e. fire damper drop testing) and inspections are completed by competent engineers.

Request a Callback

Fire Damper Testing and Inspections

Why should they be tested?

The British Standard 9999:2017 gives clear guidance that covers routine visual inspection and maintenance of ventilation and air conditioning ductwork and states that all fire dampers should be tested not exceeding a 12 months period.

The BS 9999 legislation on fire damper maintenance states that all fire dampers must be tested by a competed person after they have been installed and at regular intervals not exceeding two years.

- If you have had spring-operated fire dampers installed in your ducting, then you will need to have these tested at least every 12 months or even more frequently if they are installed in an area that is affected by high levels of dust or pollution. According to HTM03-1 fire dampers in hospitals must also be tested every twelve months.

- Unless you have certification to prove that you can safely carry out a fire damper drop test it is suitable to employ an expert who can also provide evidence of their work on each fire damper.

- Testing the fire dampers will highlight if there is anything wrong with them that could potentially cause them to fail at the duty of preventing the spread of fire. It will also allow you to evaluate the condition of each part of your fire dampers so you can plan for them to be replaced.

- According to the BS 9999 fire damper legislation, you must ensure that your fire dampers are repaired or replaced immediately if found to be faulty. It is highly recommended that you create a maintenance plan to help you budget and schedule repairs, ensuring your fire dampers remain in a fully working condition

VH001 – Fire and Smoke Damper Maintenance was released in January 2020 giving clear instruction and providing an overview of responsibilities, legislation, maintenance, reporting and competency. This is a bulleting to support existing BESA publications, BS 9999 with DW145 – Installation and Maintenance of Fire and Smoke Dampers currently under review.

Is Fire Damper testing a legal requirement?

The simple answer is yes – and regularly. There is a DOC (duty of care) on those responsible for fire dampers to make sure they are both regularly tested, and tested when they are first installed on the premises.

British Standard (BS) 9999 2017 stipulates that any dampers installed require more frequent testing than previously thought (as mentioned above they need to be at least tested annually). The use of buildings code of practice ensures those responsible must make sure to test fire safety systems and to maintain them routinely.

Fire protection cannot be provided if devices/tools (sure as spring operated fire dampers installed on premises need testing and maintenance) are faulty/out of date, thus proving the importance of testing fire dampers and ensuring they are cleaned to an optimal working condition.

What are the responsibilities regarding Fire Damper testing?

As the building owner / responsible person on-site you need to ensure that all fire and smoke dampers within your building(s) are located, serviced and tested (whether that be a drop test or otherwise). Hydro-X Fire can help to ensure you meet the regulatory requirements and support you in compiling an asset list and schedule to ensure regular checks are carried out for continued safe operation.

According to the Regulatory Reform (Fire Safety) Order 2005, it is the employer’s responsibility to maintain their fire safety systems.

- As the buildings responsible person if you are made aware of faults to any fire safety equipment and do not act on them, you could be held responsible for any implications and be prosecuted in a court of law.

- If you run a business or own a building it is your responsibility to book regular fire damper tests and ensures that a proper maintenance plan is followed.

Types of Fire Dampers

Common Fire Damper Issues

At Hydro-X Fire, not only can we install sufficient access into your ductwork systems, but we can also assist with the following fire damper services:

Fire damper installation & replacement

These come in many forms from small perforation to fire damper units located completely outside of the fire break.

Fusible Link Sourcing & Replacement:

These come in many forms and sizes and are a vital piece in the functionality of the fire damper and efficiency of the HVAC system

Your fire stopping needs to be inspected and any defects rectified to ensure the effectiveness of the fire plan and the safety of the occupants using the building

DW144 Access Panel Installation:

BS 9999 Annex W.1 Inspection and Maintenance (Note 2) states that: “The provision of access panels facilitates such cleansing, other maintenance, and also fire-fighting.”

Hydro-X Fire will analyse the above fire damper defects and suggest the most efficient solution possible. For further fire damper remedial information or to get a quote please use the contact sheet below.